A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. Gear pumps however are also widely used in chemical installations to pump fluid with a certain viscosity. There are two main variations; external gear pumps which use two external spur gears, and internal gear pumps which use an external and an internal spur gear.

Gear pumps are fixed displacement, meaning they pump a constant amount of fluid for each revolution. Some gear pumps are designed to function as either a motor or pump.The oil pump in an internal combustion engine is usually a gear type driven by the camshaft or crankshaft, or a rotor type.

[1] Oil pressure varies quite a bit during operation, with lower temperature and higher RPM's increasing pressure to a maximum of about 4 bar. To ensure that the oil pressure does not exceed the rated maximum, a spring-loaded pressure relief valve routes oil back to its source once pressure exceeds a preset limit.

[2]The oil pump usually sucks the oil out of the engine's oil pan through a wire mesh strainer and pumps the oil through an oil filter before it goes to the bearings.

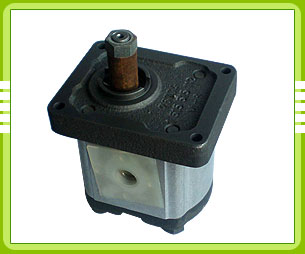

Features of our Oil Gear Pump:

- Floating Bush structure with function of automatic axial clearance compensation and also available with bearing support.

- Special abrasion resistance recipe of the bush supplied with long service life.

- The Gear Precisely machined ensured the excellent operation with low noise.

- Cold extrusion Profile Pump body can endure the pressure over 30 Mpa.

- High strength cast iron of front / back cover is more reliable to operate.

- Widely used in industrial hydraulic system of mobile mechanism, aerospace system and ocean engineering.

- Special design for harvester combines

|